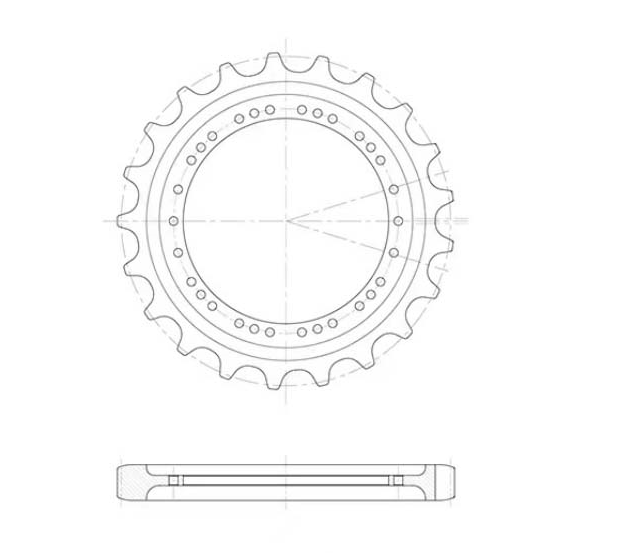

SPROCKETS FOR COMPACT TRACK LOADERS CAT239D, 249D, 259, 259B, 259B3, 259C, 259D

Undercarriage Parts Sprocket

What is an idler?

The idler is made of idler shell, shaft, O-ring, bi-metallic bushing bronze and seal group. It is made by casting or forging, machining, heat treatment, assembly, painting etc. The Idlers are used to guide the track to correct rotation to prevent deviation and derailment.

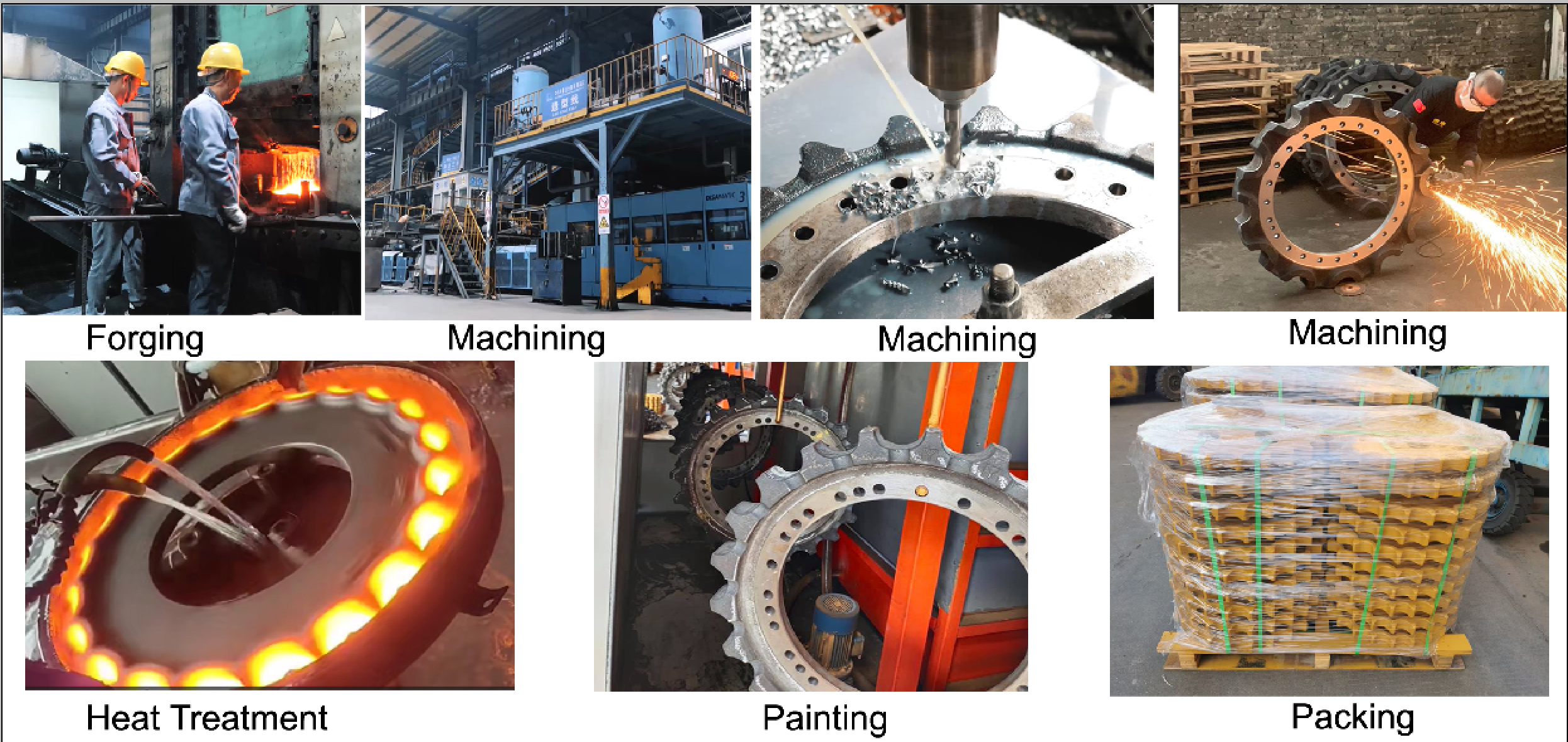

Through professional quench-tempering processes to guarantee excellent mechanical properties, our sprocket and segment have high strength and superior wear resistance to avoid bending and breaking.

Produced in advance machining center and vertical CNC turning machine for precision requirements.strict quality management ensures the effective and stable products.

Quenching depth:Root tooth 6-10mmRop tooth 18-23mm

Quality of products

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to avoid bending and breakage.

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Compatible Brands

Production Processes

Our Services

Free technical inquiries and logistic guidance with our experts.

Free repair or replace service during warranty period.

Free special services for all key construction projects.

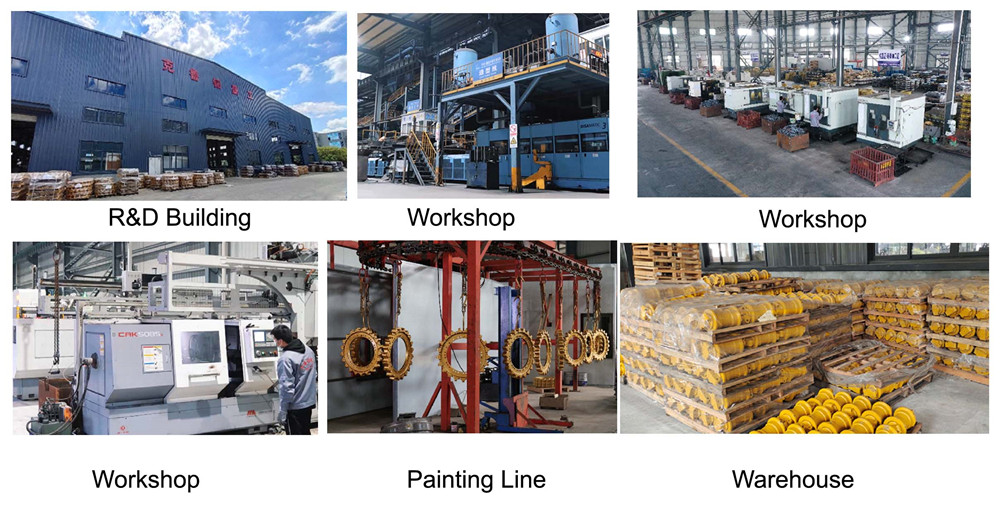

COMPANY

We are a professional of excavator and excavator undercarriage parts manufacturer in China, we can provide standardized products, also can provide customized products, to meet your various needs, create win-win cooperation

Our Factory View

Our Inspection

Our Packing