When it comes to the circuitry in excavators, it has undergone significant changes in recent decades, from simple configurations of yesteryear to today’s highly integrated and intelligent. Twenty years ago, the electrical system of excavators was relatively simple, mainly including engine start, water temperature detection, oil pressure indication, lighting and horn and other basic functions. In the past two decades with the rapid development of technology, the excavator’s electrical and hydraulic systems have realized a qualitative leap, the complexity of the electrical system an the diversity of functions increased significantly.

1. Classification of electrical system

1. Classification according to the relevance of the circuit composed of components

• Non-associated circuit: a simple circuit composed of a small number of electrical components, does not affect other circuit and components, such as lighters, horns, walking speed control and part of the liquid level detection system.

• Associated circuits: the circuits depend on each other, with external signals of self-collected signals as the control source, showing a high degree of interdependence.

2. Classified according to function

• Display system: It is used to provide real-time feedback of operation status to the driver, and the core components include sensors, meters, indicator lights, etc., such as the display of information on water temperature, water level, oil pressure, fuel level, etc.

• Control system: According to the signals collected by other components, after processing to adjust the mechanical working state of the circuit.

3. Subdivision of the control system

1. Engine control system

• Execution element: starter motor, EC motor(stepper motor), etc., sometimes including parking motor or relay.

• Signal processing element: computer EC.

• Signal acquisition components: start switch, throttle knob, speed sensor, EC sensor and various pressure switcher, etc. Some systems also use water temperature, oil pressure, water level and oil level as source signals for engine control.

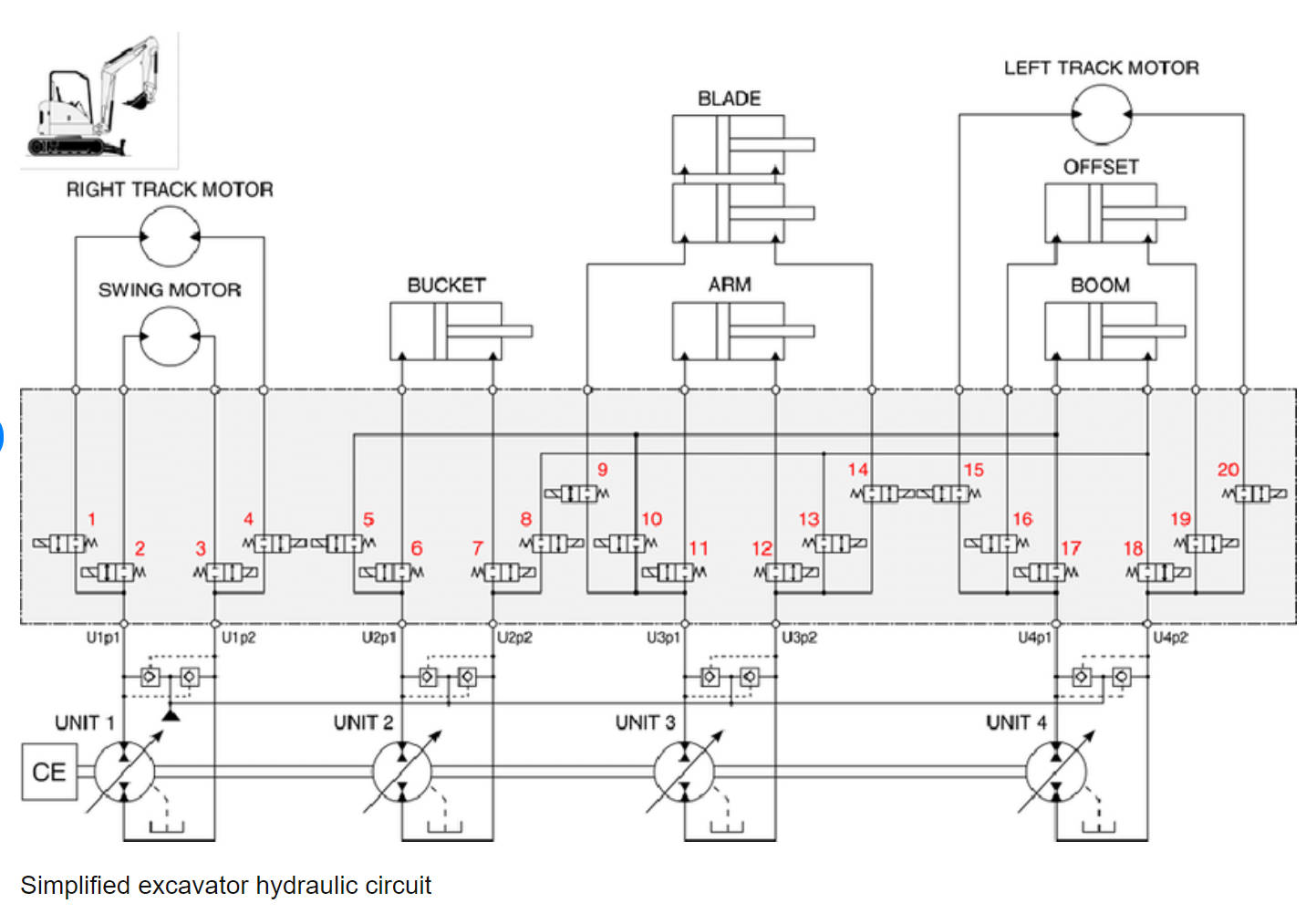

2. Hydraulic pump control system

• Execution element: pump control solenoid valve.

• Processing element: PVC computer.

• Signal acquisition element: engine speed sensor(automatic acquisition), throttle knob and operating mode switch(manual input).

3. Valve control system

• Signal source: Manual switch and pilot operated system pressure switch.

• Actuating elements: Relays and solenoid valves.

• Function: Control flow distribution

4. Other control systems

• Such as lights, horns, windshield wipers, etc., with no significant difference from other construction machinery.

With the continuous progress of science and technology, the electrical system of excavator will be more and more perfect, and each model also shows the trend of differentiation in design.

Post time: Nov-15-2024